Electronics Industry Exotic & Refractory Metals

Most people cannot imagine life without electronics in the 21st century. They power modern life, enabling communication, automation, entertainment, and innovation in countless sectors. The electronics industry spans from original equipment manufacturers (OEMs) producing vital components to end-use electronics manufacturing for consumers and businesses. Electronics manufacturers design, produce, and distribute parts, devices, and systems, including semiconductors, consumer electronics, telecommunications, and industrial automation equipment. The industry relies on metals like Tungsten, Molybdenum, Tantalum, Niobium, and Nickel Alloys like KOVAR® and INVAR® 36 across applications from circuits and capacitors to thermal management, low thermal expansion, radiation shielding, and superconductivity.

PROPERTIES OF EXOTIC AND REFRACTORY METALS IN THE ELECTRONICS INDUSTRY

The electronics industry is central to technological innovation and advancement across nearly every industry, from Artificial Intelligence (AI) and the Internet of Things (IoT) to renewable energy, healthcare, entertainment, and telecommunications. Refractory and Nickel metals are indispensable to this transformative and fast-evolving industry due to exceptional properties such as high melting points, excellent electrical and thermal conductivity, low thermal expansion, and resistance to wear and corrosion.

KEY ELECTRONICS APPLICATIONS

Electronics manufacturing is a critical process that transforms raw materials into devices like semiconductors, circuit boards, and consumer electronics. Precision, scalability, and efficiency are key, as components must operate reliably under miniaturization and high-performance demands. Challenges include thermal management, electrical conductivity, and durability, particularly in high-power or extreme environments. Ensuring consistent quality in mass production while adapting to rapid technological advancements also poses significant hurdles.

The high melting points, excellent thermal and electrical conductivity, and resistance to corrosion and wear make refractory metals ideal for critical applications like semiconductor interconnects, capacitors, and heat dissipation systems. These metals enable the industry to achieve performance, reliability, and innovation in modern electronics.

Here are some of the top sector applications and materials used.

ELECTRONICS

INDUSTRY

Refractory and Exotic Materials in Electronics Applications

Thermal Management and High-Performance Systems

Thermal management ensures performance, reliability, and longevity in high-power systems in the electronics industry. It involves controlling and dissipating heat generated by components like processors, LEDs, and advanced computing hardware, which operate at increasingly high speeds and power levels. This is vital in industries like data centers, AI-driven hardware, and consumer electronics, where compact designs and energy efficiency are priorities.

Excessive temperatures can degrade components, reduce device lifespan, and compromise performance without proper heat regulation. As electronic devices become smaller and more potent with less space for traditional cooling systems, thermal management becomes more challenging. High-performance applications like AI and 5G networks generate intense heat loads, requiring more cost-effective cooling technologies, enhanced heat dissipation for even higher speeds, and performance while maintaining sustainability.

Due to their exceptional thermal conductivity, high melting points, and resistance to deformation under heat stress, refractory metals help ensure efficient heat transfer and dissipation, even in extreme operating environments. Electronics manufacturers can use them to enhance the performance and durability of high-power electronics. Molybdenum and Tungsten, for example, are commonly used in heat sinks, heat spreaders, and thermal interface materials.

Vacuum Electronics and Advanced Imaging

Vacuum electronics and advanced imaging technologies are highly specialized high-performance electronics industry applications. Vacuum electronics, such as X-ray tubes, microwave devices, and particle accelerators, are critical in healthcare, scientific research, and industrial systems. Advanced imaging, including MRI machines and cutting-edge quantum technologies, supports medical diagnostics, space exploration, and experimental physics. These fields demand devices and systems capable of operating reliably under extreme conditions, where precision and durability are paramount.

The challenges in these sectors stem from the need to withstand extreme heat, radiation, and mechanical stresses while maintaining exacting performance standards. High-energy applications generate intense heat and expose materials to ionizing radiation. Emerging opportunities in areas like quantum computing and space exploration drive the demand for innovative technologies that push the boundaries of electronics manufacturing.

Exotic and refractory metals help form components like heat and radiation shields, essential in combination with vacuum electronics and advanced imaging in the electronics industry. They also pave the way for research, medicine, and A&D innovations. Tungsten’s high density, melting point, and radiation resistance can endure extreme conditions, vital for devices operating in harsh environments. Niobium offers key superconducting properties.

Semiconductor Manufacturing

Semiconductor manufacturing is a foundational sector in modern technology, enabling the creation of microchips and integrated circuits that serve as the “brains” of devices ranging from smartphones and laptops to autonomous vehicles and IoT systems. This industry is crucial for powering nearly every aspect of contemporary life, including communication, automation, healthcare, and advanced computing. Precision and scalability are critical due to ever-smaller chip architectures, fabricating intricate nanostructures on silicon wafers, often scaling features down to mere nanometers.

Challenges include managing the heat generated by increasingly dense and powerful chips, maintaining electrical performance at nanoscale levels, ensuring material compatibility across diverse manufacturing processes, and achieving defect-free manufacturing with incredibly tight tolerances. Yet, opportunities abound for advancements, presenting both a technical and strategic imperative for the industry.

Refractory metals like Tungsten, Molybdenum, and Tantalum offer high electrical conductivity and stability while withstanding extreme heat and corrosive environments, making them ideal for the harsh conditions of semiconductor fabrication. Their properties also enable the precise engineering required to advance semiconductor technology, ensuring performance, reliability, and scalability.

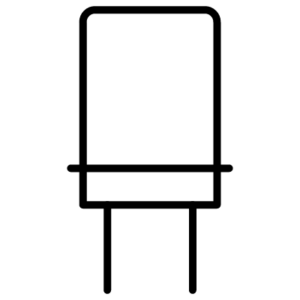

Capacitors and Power Electronics

Capacitors and power electronics are essential for energy storage and management in the electronics industry. Capacitors are key components in electronic circuits that store and release electrical energy, helping stabilize voltage, filter signals, and manage power surges. They are vital in smartphones, laptops, electric vehicles, and renewable energy systems. On the other hand, power electronics manage and convert electrical power efficiently, enabling applications such as motor drives, inverters, and energy storage systems in industries ranging from consumer electronics to aerospace and renewable energy.

These systems ensure efficient energy use, which is essential for sustainability in modern technologies like electric vehicles (EVs) and solar power. While miniaturization and increased energy density are ongoing challenges, high demand for capacitors in advanced automotive systems and renewable energy technologies presents growth opportunities.

The conductivity, stability, corrosion resistance, and heat resistance properties of several refractory metals, including Tantalum, Molybdenum, and Tungsten, make them vital elements for these electronics industry sectors. Tantalum is critical in capacitors for its high capacitance-to-volume ratio and stable performance under varying conditions. Tungsten and Molybdenum manage heat dissipation in power electronics. Their durability and conductivity enable efficient energy storage and transfer.

Industry Standards and Requirements

Industries constantly evolve, driven by a growing demand for scientific and technological advancement. Successful experimentation must ensure material integrity, safety, performance, and compliance with strict environmental and operational regulations.

These standards typically focus on aspects like purity, quality, and durability to guarantee that refractory metals meet the demanding conditions of high-stakes research applications. Because they serve multiple industries and extreme environments, this list includes more than average standards and requirements.

Standards and Requirements:

- ASTM International (American Society of Mechanical Engineers): Standards for materials used in energy applications.

- SAE Aerospace Material Specifications (AMS, formerly known as the Society of Automotive Engineers or SAE)

- ASME BPVC (Boiler and Pressure Vessel Code): Guidelines for materials used in pressure vessels and reactors.

- Department of Defense (DoD) Military Standards or Military Specifications (MIL) on the Defense Logistics Agency (DLA) ASSIST Database

We adhere to quality compliance certification standards and statutory regulations that pertain to our exotic materials, processes, custom machining services, traceability, and other aspects of our in-house expertise. Our materials specialists provide expert counsel on metal selection and inspection to ensure you receive materials that meet or exceed your expectations.

Leading Edge Metals & Alloys Certifications include:

- ISO9001:2015 and AS9100D Registered

- ITAR Registered

- NIST SP 800-171 and CMMC Complian

Our deep understanding of this industry stems from our extensive experience, skilled metallurgy professionals, and a history of successful partnerships with leading national research labs.

The Bottom Line on Materials in the Electronics Industry

The electronics industry depends on refractory and exotic metals for their unique abilities and properties. These metals enable precision, durability, safety, and conductivity for electronics, including semiconductors, capacitors, vacuum electronics, thermal management, superconductivity, advanced imaging, and quantum computing.

Why the Electronics Industry Buys Rare and Exotic Metals

High Melting Points: Essential for semiconductor manufacturing, power electronics, and advanced computing systems, where components must endure intense heat without degrading during fabrication or operation.

Strength & Durability: Crucial for electronic components in high-performance applications like aerospace, automotive, and industrial electronics, where materials face significant mechanical and thermal stresses.

Radiation Resistance: Ideal for devices like X-ray tubes, satellite systems, and nuclear power instrumentation, where components must withstand prolonged exposure to ionizing radiation while maintaining performance.

Electrical Conductivity supports the development of high-performance semiconductors, capacitors, and power systems, enabling efficient energy transfer in devices such as smartphones, electric vehicles, and renewable energy systems.

Thermal Conductivity and Thermal Expansion Stability: This allows efficient heat dissipation in high-power electronics, such as processors, LEDs, and power inverters. It ensures system stability and prevents damage from overheating while closely matching the thermal expansion of ceramic and silicon chips.

Formability: Enables the creation of precise, complex components, such as thin-film layers, interconnects, and microfabricated structures, ensuring optimal performance and meeting the rigorous demands of modern electronics manufacturing.

Key Metals We Offer for Electronics Manufacturers

Molybdenum: With its high melting point, mechanical strength, and thermal conductivity, molybdenum is ideal for semiconductor fabrication, power electronics, and thermal management in high-power systems. It maintains structural integrity under thermal stress, making it indispensable for heat spreaders, thin-film transistors, and other precision applications. Explore Molybdenum

Tungsten: Essential in semiconductor manufacturing as a heat-resistant material for interconnects, contacts, and heat sinks due to its exceptionally high melting point (over 3,400°C) and density. It is also an effective radiation shield in X-ray equipment and vacuum electronics. Tungsten’s high density makes it invaluable for compact designs requiring thermal stability and precision. Explore Tungsten

Nickel: Known for its low thermal expansion, corrosion resistance, and excellent electrical conductivity, nickel is widely used in electronics for components such as connectors, terminals, and batteries. Its ability to maintain structural integrity under varying temperatures makes it a preferred material for applications requiring stable performance in high-temperature environments. Explore Nickel

INVAR® 36: A unique alloy of iron and nickel, INVAR is renowned for its exceptionally low thermal expansion, making it ideal for precision instruments, optical systems, and semiconductor devices. Its stability over a wide range of temperatures ensures reliable performance in applications where dimensional accuracy is critical, such as in the aerospace and defense sectors. Explore INVAR 36

KOVAR®: An alloy of iron, nickel, and cobalt, KOVAR has a coefficient of thermal expansion closely matched to that of glass, making it indispensable for sealing applications in electronics. It is commonly used to manufacture vacuum tubes, semiconductor packages, and electrical feed-throughs where low thermal expansion and high strength are essential. Explore KOVAR

Tantalum: Widely used for its high melting point, corrosion resistance, and excellent electrical conductivity in high-performance capacitors, critical for smartphones, electric vehicles, and renewable energy systems. It is also applied as a diffusion barrier in semiconductor devices, ensuring material integrity during fabrication. Explore Tantalum

Niobium: Known for its excellent formability and superconducting properties at cryogenic temperatures, niobium is a key material in emerging quantum computing applications and advanced imaging systems like MRI machines. It also supports high-frequency electronics by enabling efficient energy transfer. Explore Niobium

Zirconium: While less common in general electronics, zirconium’s corrosion resistance and thermal stability are useful in specialized components like electronic substrates and advanced thermal barriers. Its low thermal expansion and stability under extreme conditions are advantageous in niche applications. Explore Zirconium

Other Exotic & Refractory Metals: These are the top materials used in the electronics industry that we support the most. They are not the only ones, though, and most metals play a role in this ecosystem. Explore Materials