How to Buy Part 3: Metal Properties, Formats, and More

THE PURCHASING PROCESS FOR SPECIALTY METALS BUYERS

The purchasing process for exotic and refractory metals and the applications that depend on them is complex. We’re making it easier for you with a 3-part series on how to buy them. Part 3 is focused on metal properties, formats, and other ordering considerations.

As a reminder, the series will culminate in a handy downloadable guide that aims to simplify, streamline, and optimize your specification and purchase journey by covering:

Part 1: Applications, related exposures, machining, and standards

Part 2: Conditions, surface conditions, and other properties of metal

Part 3: Formats and other considerations

Recap & PDF: Brief summary with key links and an option to download the series as a single PDF file

Let’s dig into the remaining elements of metal properties, formats, and final considerations.

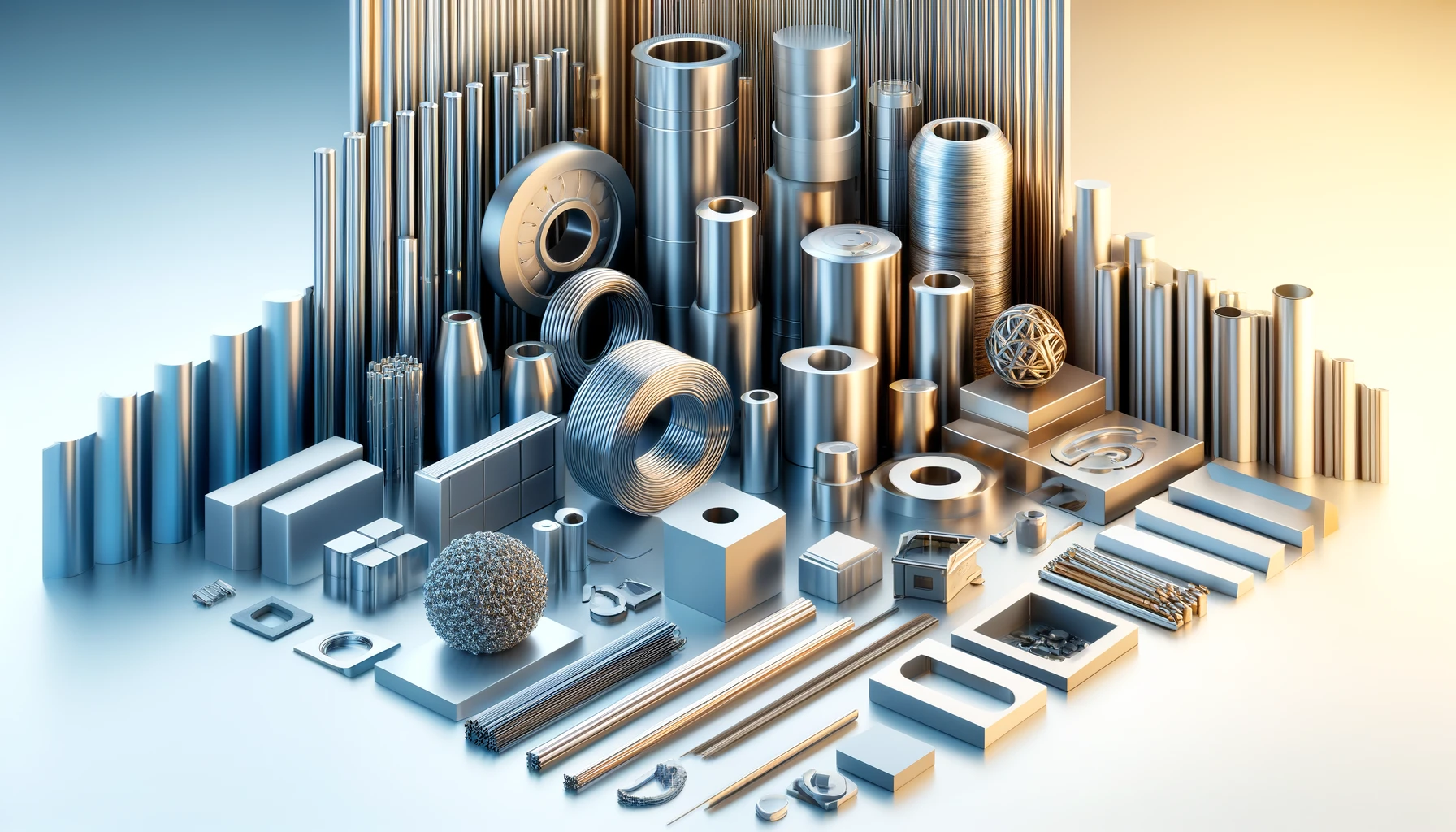

Metal Properties and Material Formats

Metals come in several formats. Overall, the format is determined by the metal properties and the necessary thickness or diameter of the product. Here are the primary formats our customers require in order by their typical dimensions, from the thinnest and smallest to larger, more substantial forms:

Foil: A very thin sheet of metal, typically less than 0.2 mm (0.008 inches) in thickness, used in applications requiring lightweight and highly flexible metal properties.

Wire: A long, thin strand of metal with a small diameter, typically used in electrical applications, binding, and structural reinforcement.

Sheet: A flat piece of metal with a thickness greater than foil but typically less than 4.75mm (0.187 inches), commonly used in fabrication and construction.

Plate: A flat piece of metal with a thickness typically greater than 4.75 mm (0.187 inches), used in structural applications and heavy machinery.

Rod: A solid cylindrical piece of metal with a larger diameter than wire, used in various structural, manufacturing, and engineering applications.

Bar: A solid piece of metal with a rectangular, square, or circular cross-section used in construction, manufacturing, and engineering applications.

Tube: A hollow cylindrical piece of metal with a relatively thin wall, used for transporting fluids and gasses or as structural components with robust metal properties.

Pipe: A hollow cylindrical piece of metal with a thicker wall than a tube, used primarily for conveying fluids and gasses under pressure.

Billet: A solid, semi-finished piece of metal with a circular or square cross-section, typically used as a starting material for rolling, forging, or extrusion.

Ingot: A large block of metal cast in a specific shape for convenient handling and further processing into sheets, bars, or other forms.

Extrusion: A process where a material with metal properties suitable for machining is pushed through a die to create long shapes with a consistent cross-section, such as rods, tubes, or complex profiles.

Other Considerations for Specialty Metal Orders

Chemistry: While we sell most materials in their pure form, some are available as alloys to enhance certain metal properties. You might need certain specialty chemistry for your application, and we can make that happen based on the details you share in your specifications.

Testing: You may also require testing for factors such as machinability or magnetic permeability. Standard tests include tensile, mechanical, hardness, bendability, pressure, Charpy impact, and fracture toughness as required by the applicable specification. Specialty tests may also be required based on specific metal properties needed.

Nuanced Metal Properties and Ordering Information to Get What You Need

Now we’re really getting down to it. Below is just a taste of the metal properties you’ll be looking for per each exotic or refractory metal we sell. Click on the link to each individual materials page to see the relevant ASTM specifications and AMS specs for that metal. Also, take a look at our Compliance and Quality page for more information.

Tantalum

Tantalum products, such as rod, bar, foil, sheet, and plate, are produced to ASTM B365 and ASTM B708 standards. They are available in various alloys, such as R05200 (Pure Ta) and R05252 (Ta2.5%W).

Tungsten

Pure Tungsten foil, sheet, and plate are produced to ASTM B760 standards. They are available hot or cold-rolled and are often supplied stress-relieved.

Tungsten Alloys

Heavy metal tungsten alloys are produced per ASTM B777 or AMS 7725. Depending on the tungsten content and required density, these materials are available in various classes. Nominal tungsten content can range from 90-97.5%, and densities range from 17-18.5 g/cc.

Molybdenum and TZM

Flat molybdenum products are produced to ASTM B386, while round products are to ASTM B387. Common grades include Molybdenum 360 (pure Arc-Cast), 361 (pure standard powder metallurgy grade), 363 vacuum arc-cast TZM), 364 (powder met TZM), and 365 (vacuum arc-cast Mo30%W).

Niobium and its Alloys

Niobium products are produced according to ASTM B392 (Bar, Rod, and Wire), B393 (Strip, Sheet, Plate), and B394 (Seamless and Welded Tubes) standards, as well as various AMS specs when needed. It is known for its high melting point and resistance to most acids.

KOVAR®

Kovar® materials, produced to ASTM F15, are available in various formats and tempers, making them suitable for deep drawing applications.

INVAR 36®

Invar 36® is typically produced per ASTM F1684. It is essential to specify the required temper for the application.

Titanium

Titanium products, like Ti 6Al-4V, are produced to ASTM B265 and AMS 4911 standards. They can be heat treated to improve strength.

Nickel

Nickel 200 and 201 are produced per ASTM B162, B160, and B161 standards. They are available in various tempers and surface conditions.

Zirconium

Pure Zirconium products are produced to ASTM B551 and ASTM B352 standards. Round products are produced to ASTM B550 and ASTM B351 standards.

The Easiest Thing is to Talk to Our Pros

Contact us to discuss specialty, refractory, and exotic metals or request a quote to cut right to the chase. Sign up to receive our monthly newsletter, and join the conversation on LinkedIn.

We compiled this information and developed this article meticulously under the watchful eye of our Chief Metallurgist, Bob Desberg. Except for our Chief Morale Officer Bonzo, who had no paw in this article, we are human. If you see anything missing or incorrect, please advise us and we’ll be sure to update or correct it!